Screw Plug Heat Exchangers(SRXTM)

Screw Plug Heat Exchanger(SRXTM)

Our Unique Added Steel Ring™ technology with enclosure offers exceptional safety and maintenance advantages over other Breech Lock enclosures. It prevents bell-mouthing of the threaded portion to guarantee quick opening of the plug during time-critical turnaround operations. The use of the latest technology ensures there is no intermixing of fluids from the gasketed joint between the shell side and the tube side.

Stacked Screw Plug Exchangers ( SRX™)

Metallurgy:

LAS, SS, Inconel, and a range of clad combinations.

Design Pressure:

151.2 Kg/m^2g

Design Temperature:

450 DegC

Highlights:

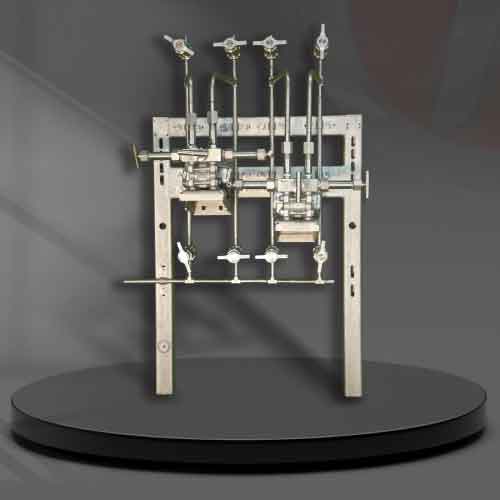

High-pressure Screw Plug Exchanger

Country of Supply:

Oman

Year of Supply:

2020

Read More

Metallurgy:

LAS, SS, Inconel and a range of clad combinations

Design Pressure:

151.2 Kg/m^2g

Design Temperature:

450 DegC

Highlights:

High-pressure Screw Plug Exchanger.

Country of Supply:

Oman

Year of Supply:

2020

HDO Feed/Effluent Exchanger (SRX™)

Metallurgy:

CS, SS Inconel & Hastelloy

Design Pressure:

151.2 Kg/m^2g

Design Temperature:

427 DegC (Shell side & Tube side)

Highlights:

Multi Screw Plug Heat Exchangers with Inconel & Hastelloy Tubes. And different combinations of clad like CS with SS overlay, CS with Inconel overlays

Country of Supply:

USA

Year of Supply:

2008

Read More

Metallurgy:

CS, SS Inconel & Hastelloy

Design Pressure:

151.2 Kg/m^2g

Design Temperature:

427 DegC (Shell side & Tube side)

Highlights:

Multi Screw Plug Heat Exchangers with Inconel & Hastelloy Tubes. And different combinations of clad like CS with SS overlay, CS with Inconel overlays

Country of Supply:

USA

Year of Supply:

2022

Hi-Low Feed Reactor /Effluent Exchanger ( SRX™)

Metallurgy:

CS, Low alloy steel, and SS

Design Pressure:

150 Kg/m^2g (Shell side) and 128.5 Kg/m^2g (Tube side)

Design Temperature:

314 DegC (Shell side) and 360 DegC (Tube side)

Highlights:

LAS overlay with SS, High Thickness of 295mm

Country of Supply:

India

Year of Supply:

2008

Read More

Metallurgy:

CS, Low alloy steel, and SS

Design Pressure:

150 Kg/m^2g (Shell side) and 128.5 Kg/m^2g (Tube side)

Design Temperature:

314 DegC (Shell side) and 360 DegC (Tube side)

Highlights:

LAS overlay with SS, High Thickness of 295mm

Country of Supply:

India

Year of Supply:

2019

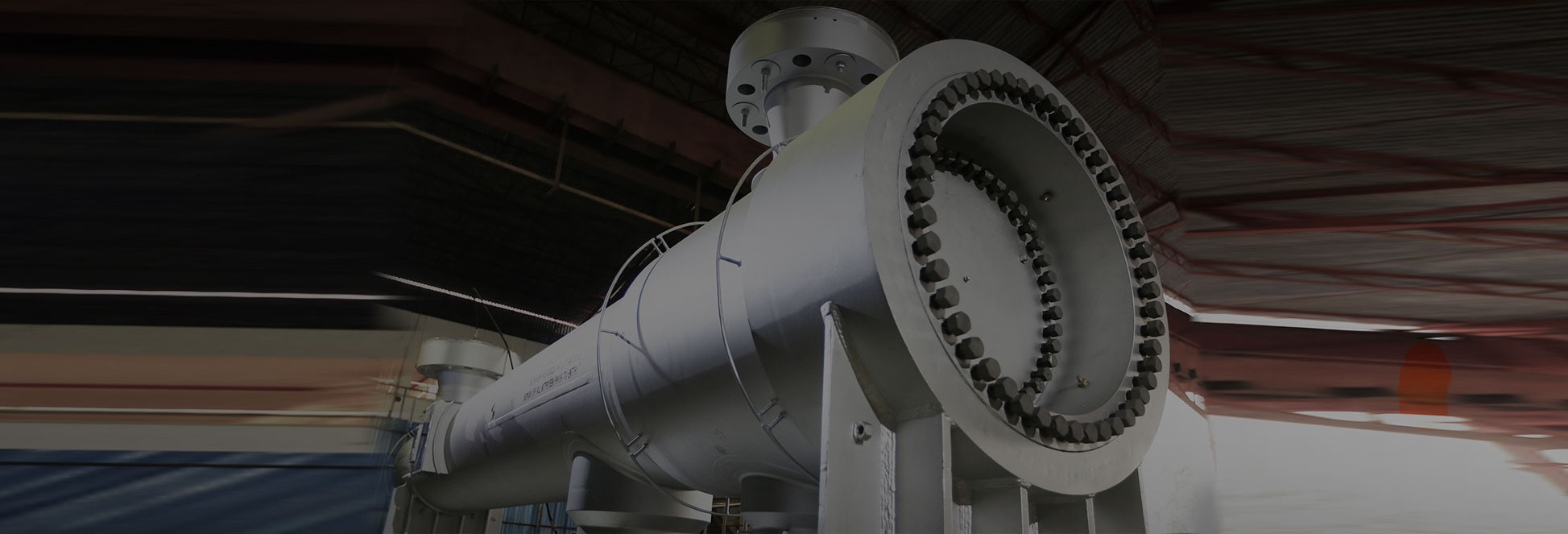

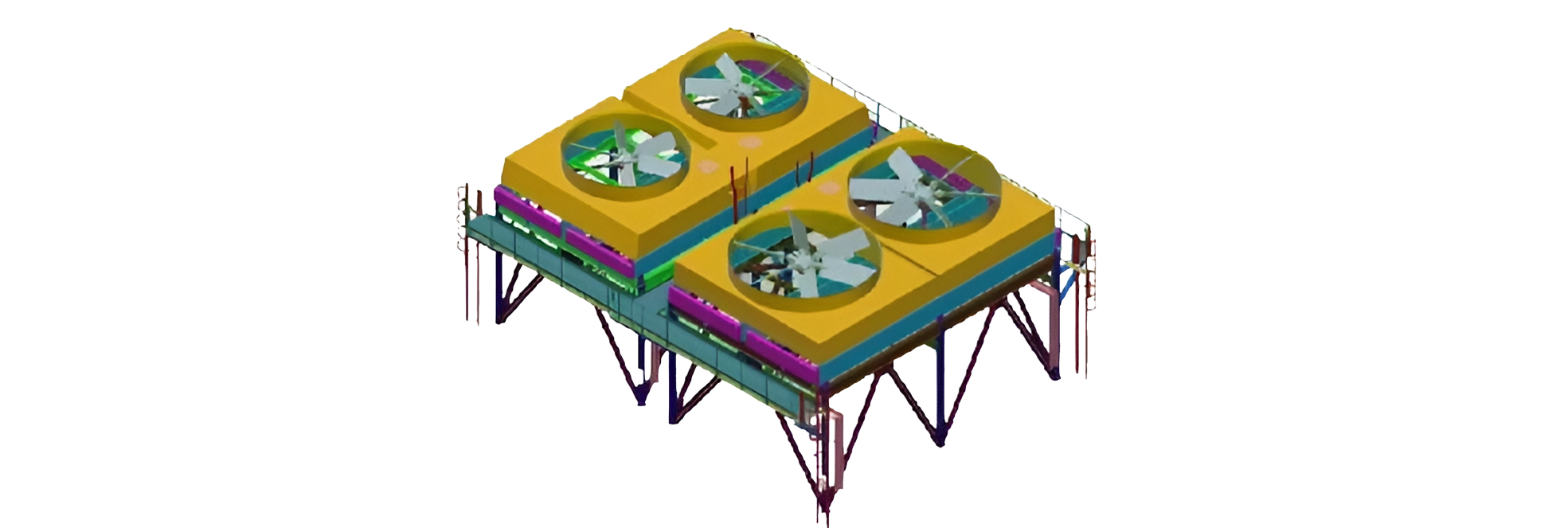

Air Cooled Heat Exchangers

An air-cooled heat exchanger is a device that cools hot fluids using air, without needing water. There are three main types: forced draft, induced draft, and natural draft. They’re built tough to handle tough conditions, meeting ASME Division I and II standards.

These exchangers are carefully designed, with strong headers analyzed using FEA. Different types of headers are used based on specific needs. In cold areas, they might have louvers or recirculation systems for winter.

Detailed drawings are made from 3D models, with specs for fans, motors, sensors, and more. Vendor documents are reviewed to ensure quality.

For high-pressure units, the tube bundle is analyzed to make sure it can handle the pressure. This ensures these heat exchangers are efficient, durable, and safe in industrial settings.

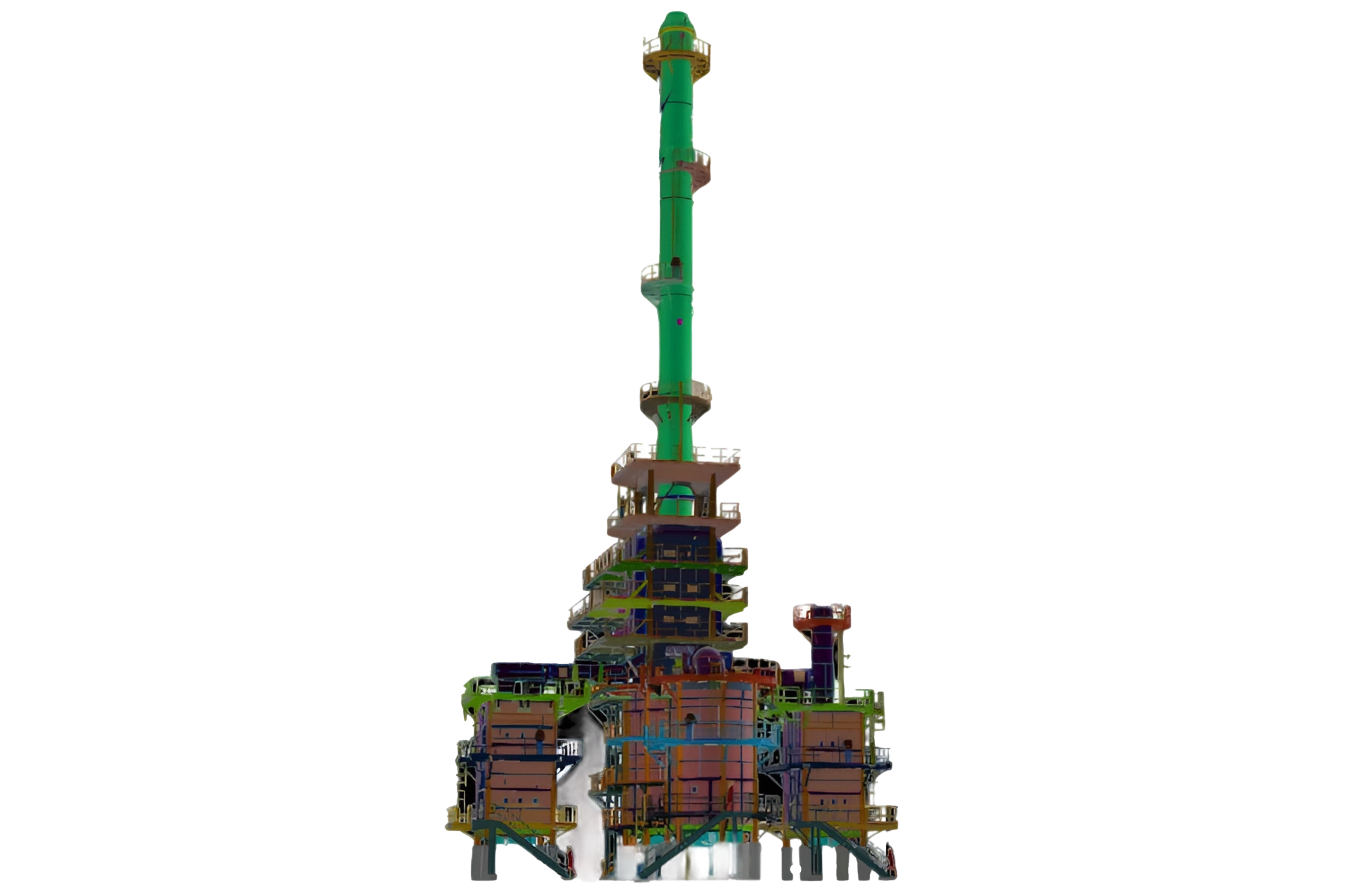

Fire Heaters

Fire heaters are essential equipment used in process industries to heat various substances such as water, oil, and chemicals. They employ combustion to generate heat, which is transferred to the substance in a controlled manner, facilitating specific processes like distillation, refining, and separation.

There are different types of heaters, each with its own airflow mechanism, like natural draft, forced draft, induced draft, and balance draft. Some heaters have air preheater systems to make combustion more efficient.

Designing heaters involves careful calculations for thermal, mechanical, and structural aspects to meet industry standards. 3D models are used to make fabrication easier.

Specifications are made for items like burners, fans, and doors. Sometimes, studies are done to make heaters work better.

Vendor documents are checked to make sure they match design specifications. Drawings are made for manufacturing.

Finite element analysis is used to make sure parts like tube support castings are strong enough for different conditions. This helps ensure heaters are reliable and efficient in industries.